Graphene enables optoelectronics on regular paper

Graphene enables optoelectronics on regular paper

(Nanowerk Spotlight) Electronic devices that source, detect and control light – i.e. optoelectronic devices – come in many shapes and forms. In the field of nanotechnology, materials like nanofibers (see for instance: "Light-emitting nanofibers shine the way for optoelectronic textiles") and carbon nanotubes have been used and especially graphene has shown exciting potential for optoelectronic devices.

Electronic paper is a particularly attractive application aiming to reconfigure the displayed information electronically on a sheet of common printing paper. Paper-based substrates have been an ambition of research in various fields ranging from medical diagnosis to display technologies aiming to create low cost and ubiquitous devices.

For example, paper-based microfluidic devices ("Active microfluidic chips inkjet-printed on normal paper"), electronic circuits ("Towards self-powered electronic papers"), even robotic systems have been developed.

In terms of display technology, several techniques have been developed based on electrophoretic motion of particles, thermochromic dye, electrowetting of liquids, to realize electronic paper (e-paper) that has great potential for consumer electronics.

Contrasting the primary aim of e-paper, most of these technologies, however, are not compatible with conventional cellulose-based printing papers.

With this motivation, using multilayer graphene as an electrically reconfigurable optical medium, researchers in Turkey have demonstrated an optoelectronic framework compatible with conventional printing paper.

"The realization of optoelectronic devices on paper has been an outstanding challenge due to the large surface roughness and incompatible nature of paper with optical materials," Dr. Emre O. Polat, a post-doctoral researcher in the Nano-Optoelectronic Group at ICFO-The Institute of Photonic Sciences in Spain, tells Nanowerk. "We have now demonstrated a new class of optoelectronic devices on a piece of printing paper using graphene as an electrically reconfigurable optical medium.

"Reporting their work in the June 1, 2016 online edition of ACS Photonics ("Graphene-Enabled Optoelectronics on Paper"), first-authored by Polat, a team from Bilkent University (where Polat worked prior to ICFO) shows that multilayer graphene on paper can be used as an electrically reconfigurable medium for display applications.

"We anticipate that our results provide a significant step for realization of low-cost, disposable and ubiquitous optoelectronics on unconventional substrates," notes Polat.

Optical properties of graphene can be controlled by doping. Doping alters the rate of interband and intraband electronic transitions of graphene and yields electro-modulation of optical absorbance in a very broad spectrum.

Optical contrast achieved by atomically thin graphene is limited by the optical absorption of 2.3%, which is defined by fundamental constants.

"In our previous work (Scientific Reports, "Graphene based flexible electrochromic devices"), we showed that multilayer graphene films yield high-contrast optically reconfigurable medium which is suitable for display applications on unconventional substrates," explains Polat. "In our new research, by integrating a large area multilayer (ML) graphene on a piece of printing paper, we managed to fabricate optoelectronic devices on paper using electro-modulation of graphene layer via reversible intercalation process.

"The paper device consist of two multilayer graphene layers transfer-printed on both sides of the paper. In this configuration, multilayer graphene simultaneously operates as the electrically reconfigurable optical medium and electrically conductive electrodes.

In addition, the paper substrate yields a flexible and foldable mechanical support for the graphene layers and it holds the electrolyte (room temperature ionic liquid) in the network of hydrophilic cellulose fibers.

"Cutting, folding, and printing are common processes for paper, but not for optical materials," Polat points out. "Combining these scalable methods with our paper devices opens new possibilities for novel optoelectronic devices. Moreover, we demonstrate the graphene as a new class of flexible and foldable electrochromic material which simultaneously offers all key requirements for practical applications; high-contrast optical modulation over a broad spectrum, good electrical conductivity and mechanical flexibility.

"This present work is a proof-of-concept ultra-thin electrochromic displays on a piece of paper. The team's aim is to convert the proposed device structure to a product level electronic paper by including the readout circuit and increase the resolution of the display by decreasing the individual cell size. The researchers illustrated the promises of the method by fabricating multi-pixel display devices on paper.

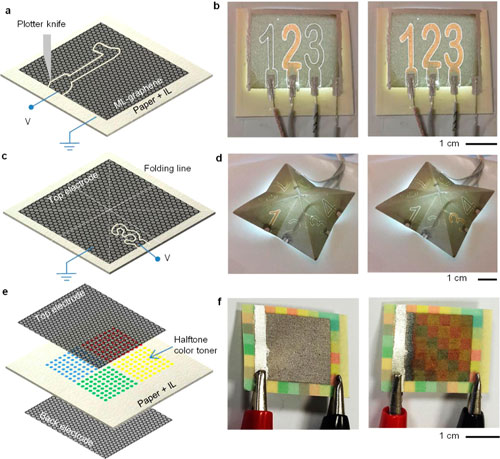

Planar, 3D, and colored display devices on paper. (a) Schematic drawing of the planar paper display fabricated by patterning multilayer graphene electrode into isolated elements using a plotter. (b) Photograph of the operating device. The color of the isolated elements can be controlled individually. (c) 3D paper display fabricated by folding the planar paper device into three dimensions. The display elements are patterned on planar device. (d) Photograph of the operating device with back illumination. The multilayer graphene electrode preserve its electrical continuity after the folding. (e) Schematic drawing of the color device formed by printing halftone color toner on paper sandwiched between two multilayer-graphene electrodes. (e, f) Photograph of the working device at 0 and 4 V bias voltage. (Reprinted with permission by American Chemical Society) (click on image to enlarge)

The key attributes of the team's devices are the simplicity of device architecture, high optical contrast and broad band operation. Compatibility with roll-to-roll fabrication processes enables scalable approaches for large area applications such as e-paper.

"Since the paper is not compatible with the chemical fabrication steps due to its rough surface and physical instability, the main challenge is to develop alternative fabrication techniques devoted for the graphene-on-paper technology," Polat concludes. "We have already made great progress on developing smart fabrication steps, however there are still some technical challenges to be solved regarding proper encapsulation."